What are Belted Tires?

Posted by Agota Szabo on Jun 22nd 2022

Currently, a typical tire on the market has two belts as part of its internal materials. Meanwhile, the number of three-belted tires is also rising. The demand is high, but why do tire belts matter exactly? What do they have to offer that is lacking in simpler constructions?

Tire brands are constantly on the verge of introducing new technologies. In the 1960s, U.S. tire manufacturers started to produce belted tires. This was their reaction to the European-made radial tires that offered the most durability at that time.

Before that, American bias-ply tires were ruling the market. However, they were significantly worse in terms of longevity. The competition-driven developmental process, with the production of more durable tires with a longer lifespan, followed this.

What are Belted Tires?

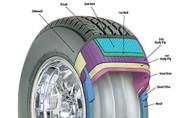

Tires can be belted with various strong materials. If the tire's structure is reinforced with one or more layers of steel cord or fabric, then it's a belted model. While the tread is the tire's first layer, the belt is the second one, and then comes its inner lining that holds the air inside.

This is a great way to make the whole tire structure stronger while not making it thicker in the process. This characteristic is particularly important for ultra high performance tires. The belt can be considered a single, tough unit that is there to maintain the tread's stability in the long term.

What are Belts?

There are numerous different materials that can be used to manufacture a belted tire. This usually involves a complex compounding and weaving process. The resulting tires can withstand more heat, more load, and harder hits throughout the ride.

Manufacturers use rayon, fiberglass, steel, and other materials to strengthen the structure of their tire models. They insert layers right under the tread rubber, usually in the form of cords that crisscross each other at certain angles.

Belted tires can come with many benefits, including better traction, extra strength, and impact resistance. These types of tires are increasingly common in the market. Below, we are going to answer some of the most important questions about belted tires.

Do All Tires have Belts?

The boost in quality is so significant that most tire manufacturers can't afford to not use belts in their models. Passenger radials, for example, come with two or three steel belts. Top-rated items are usually reinforced with steel and various other materials that support their structure.

High speed tires are reinforced with an emphasis on durability, heat resistance, and traction. These are the most important qualities a high performance vehicle needs from a tire set. Other tires such as off-road ones are optimized for impact absorption to guarantee a smoother ride.

Types of Belted Tires:

There is a great variety of belted tires being manufactured in the industry for various purposes. We can divide them into two categories right away: radial tires and bias-ply tires. There are some significant differences between the two, each of them coming with its own benefits and downsides.

Belted Radial Tires

In belted radial tires, the steel belts run perpendicular to the tire's direction. With the steel-belted structure, the tire can withstand the vehicle's weight and to hold the air pressure. It also promotes a smoother ride, as it deals pretty well with heat build-up at high speeds.

Reinforced radials last longer and are more flexible than bias-ply tires. Their increased flexibility results in better traction and road contact.

Belted Bias Ply Tires

Bias-ply tires come with two or more layers of nylon cords under the tread rubber. Belted bias-ply tires, on the other hand, have additional belt layers in the tread. These are usually steel and often a couple of additional tough materials as well.

The materials strengthen the tire's carcass. This enables a bias tire to better resist deformations, relying on the rigid inner materials.

Other Ply Types:

There are various other ply types that can improve tire stability by a great deal. This really depends on the car you drive. It's about choosing between off-road durability, on-road performance, or pure load capacity.

If you are on the search to find the best reinforced tire, then continue reading below. Based on the information, it is going to be easier to find the one that works fine for your vehicle.

Polyester Plies

Many tire manufacturers use polyester tire cord fabrics in their manufacturing process. This is one of the popular options available when it comes to reinforcing the tire structure. With the polyester cords, the tire can better hold the vehicle's weight while maintaining its shape.

Steel Belts

While thinking about ways to reinforce a tire, using metal is one of the first things that comes to mind. When tire engineers took this approach, they found out that using steel is among the best options.

Since then, tire production has been widely using steel belts. Steel cords in tires make them stronger and more durable. Steel is also highly effective against heat build-up and improves the tire's puncture resistance.

Cap Plies

Cap plies go under the tread rubber and they wrap over the steel belts to strengthen the tire's construction. While the steel cords are the high-strength components that reinforce the tire, the woven cap plies are there to hold the cord edges.

They are rubberized parallel nylon cords that reduce the centrifugal load on the tire. It is a physical restriction on the belt edge that lowers internal tension. As a result, sockets are less likely to develop in the tread. Cap plies also make the tire more resistant to heat, slowing down the aging process.

Aramid or Kevlar

Aramid and Kevlar are reinforcement materials brands use for premium tires in the off-road category. Kevlar is widely used for bulletproof vests, as it can withstand the force and shock caused by a bullet. For light trucks, ATVs, UTVs, and SUVs driven hard on uneven terrains, impact absorption is very important.

Bumps or even potholes slowly but surely destroy traditional radial tires. With proper ply separation, the tire brand builds aramid or kevlar cord into the tread and the sidewall. The best thing about these alternatives is that they don't add weight to the tire.

They stiffen the whole tire, which offers better traction and helps a lot during cornering and handling overall. The technologies reduce squirming on loose, muddy, and uneven terrains. As an extra benefit, they decrease rolling resistance by preventing heat build-up.

Nokian and Goodyear are two tire brands that use aramid and kevlar fibers with their tire models.

Frequently Asked Questions (FAQs):

Are Belted Tires Better?

Belted tires don't expand in diameter like non-belted tires do at high throttle input. This makes their footprint wider and their sidewall harder. They have a strong structure throughout the drive with a consistent sidewall feel and a fixed contact area. Consequently, they provide seamless handling.

Are Steel Belted Tires Better?

Steel belted tires are flexible due to the fact that there are fewer layers in their construction. Steel belts mounted underneath the tread reinforce these tires, right on top of the fabric belts. Tires with steel belts promote damage protection and high overall durability despite the few layers.

Are Belted Bias Tires Good?

Belted tires are good in the sense that they promote a strong structure. Their construction consists of two steel belt layers and two or more layers of nylon under the tread. It results in a network of inner materials in the form of rigid cords that bond to the tread and greatly reinforce the tire carcass.